Composition

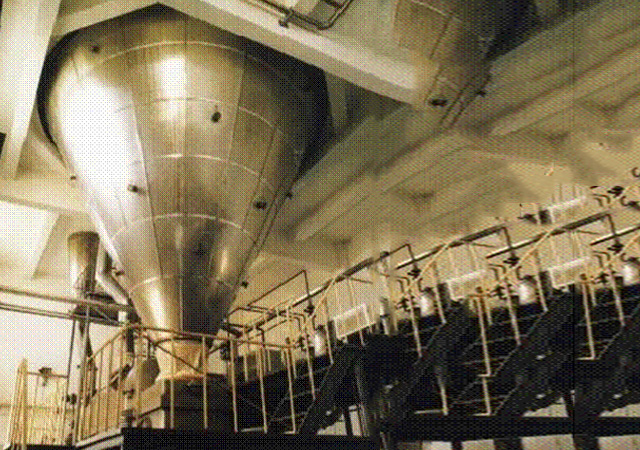

Our drying tower system mainly consists of the spray drying tower, fluidized bed, vibration sieve, blower, air filter, air heater, atomizer, cyclone separator, exhaust fan, a concentrated milk tank, high pressure pump and so on.

Working Principle

Here we take the spray drying process of milk to illustrate the working principle of our spray drying tower equipment. During the drying process, the concentrated milk is dispersed into atomized emulsion droplets (having a diameter of 10-15um) through the atomizer. In this way, the surface area of the milk is greatly enlarged.

In addition, the emulsion droplets contact the hot air fed in beneath them and the vapor will be removed by the hot air and exhausted from the exhaust outlet of the drying chamber. The whole drying process takes only 10~30s.

Advantages

The drying tower system produced by our company is especially appropriate for drying heat sensitive materials. It is able to dry products causing little protein denaturation. The whey protein solubility of the dried product remains and the enzyme activity dose not lose.

Milk powder dried by our spray drying system remains its original nutrients, color and flavor. Moreover, the milk powder that our drying tower system fabricates also has high solubility and is easy to reconstitute.