This complete milk powder production line features direct standardizing system for fat content. Normally, whole milk powder, which is produced with standardized milk, is not homogenized. Our milk powder production machine applies high-duty heat treatment to inactivate lipases. High-temperature pasteurization is needed in case of negative Peroxidase test results.

This powdered milk making equipment utilizes falling-film evaporator for concentration. The concentration process normally has to be conducted two or more times to ensure that dry solid content is between 45%-55%.

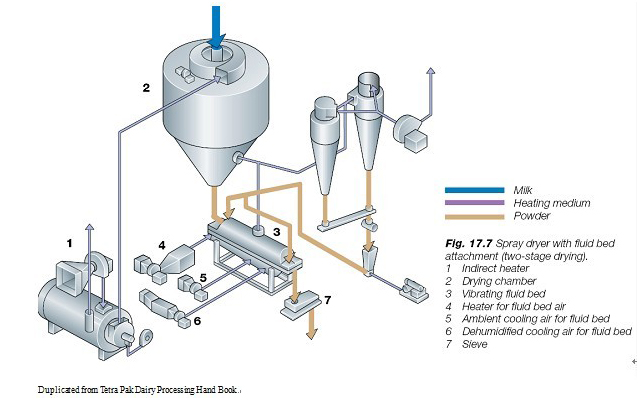

Two-Stage Drying

1. The very last partition of water contained in milk is the hardest to remove and requires higher drying temperature at outlet. However, higher temperature may come with negative effects on powder quality. Therefore, it is essential to keep lower temperature at outlet during milk powder production. If water content is still higher than standards, we will introduce two-stage drying after spray drying process.

2. The first drying stage in our milk powder production line is spray drying, and the second stage is fluid bed drying. Milk powder transferred from drying chamber comes with moisture content 2%-3% higher than standard. Then the fluid bed dryer is used to remove redundant water and cool milk powder.

Milk powder is derived from liquid milk by drying process, where aromas, flavors and color as well as key elements such as protein, fat, carbohydrate, vitamins and minerals, etc., are perfectly retained. Furthermore, other factors are also essential including uniformed moisture content, solubility, dispersability and wettability as well as particle structure, size and distribution.

This beverage production line offers various package methods, such as can, paper bag, laminated bag or plastic bag. Other choices are available upon request.

Components of Complete Milk Powder Production Line

1. Water Treatment Section

2. Milk Receiving Section

3. Preparation Section

4. Concentration Section

5. Drying Section

6. Packaging Section

7. CIP Cleaning Section

8. Compressor

9. Boiler

10. Cooling Device

11. Installation Material

| Raw Material | Fresh Raw Milk |

| Product | Whole Milk Powder, Sweet Milk Powder, Skimmed Milk Powder, Infant Milk Powder , Formulated Milk Powder, etc. |

| Production Capacity | 1.5 tons/d to 100 tons/d |

| Package | Tin, Plastic Bag, etc. |